Products

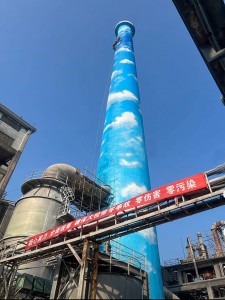

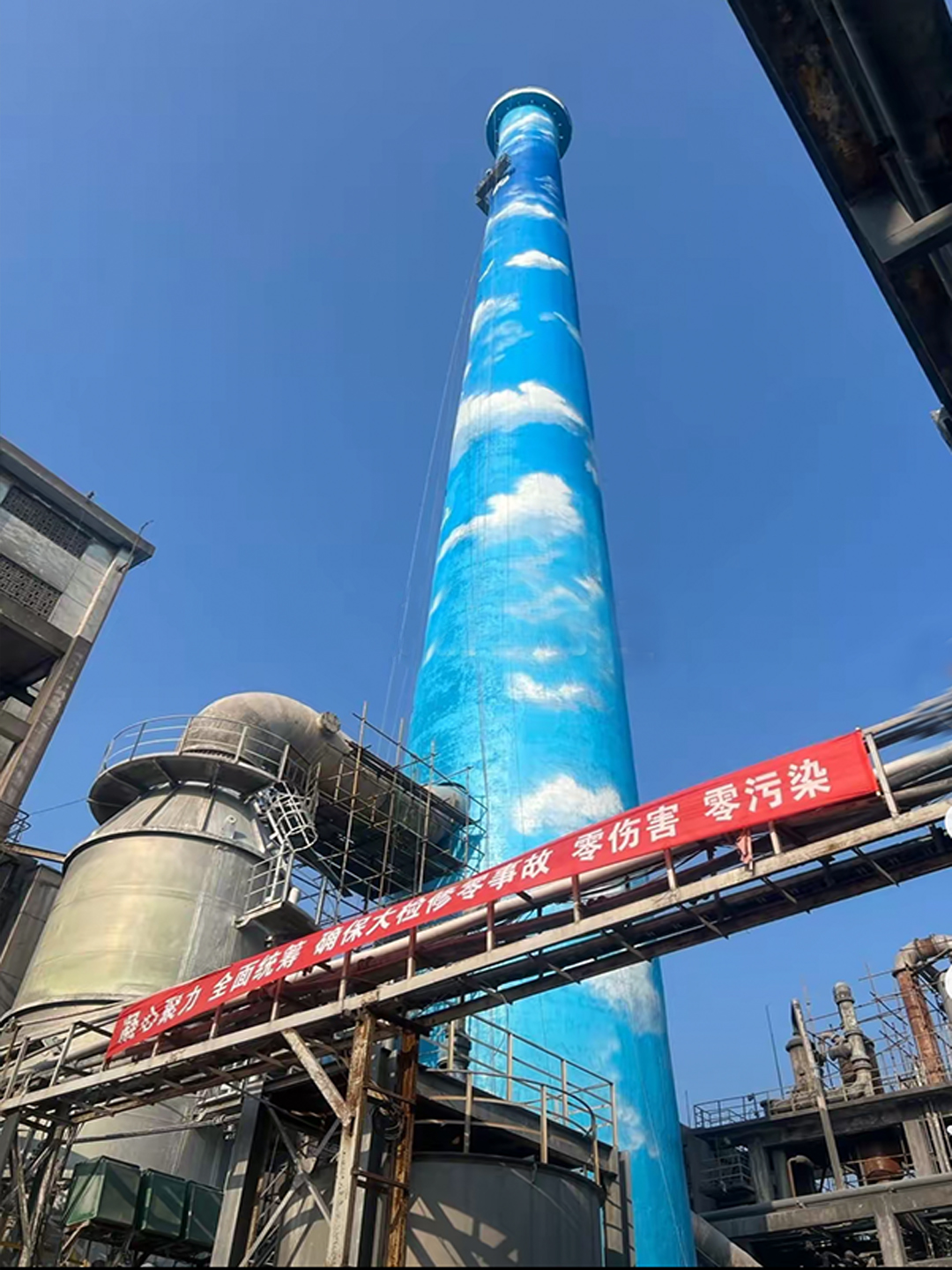

chimney landscaping painting

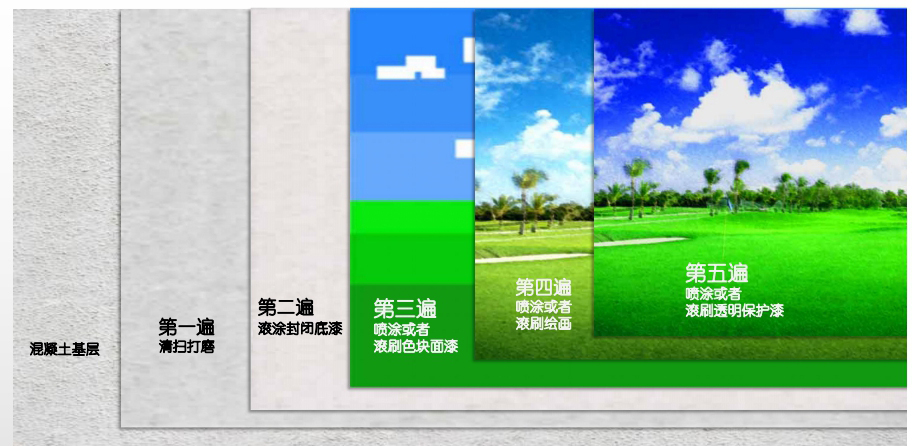

Construction process:

Tower wall base layer treatment→ tower wall crack repair→ polymer mortar repair, leveling → rolling pure epoxy sealing varnish the first pass→ spraying acrylic polyurethane topcoat→ spraying acrylic polyurethane topcoat, second pass→ tower wall landscaping → equipment removal→ site cleaning → final acceptance

Grassroots treatment

2.2.1 For uneven surfaces (including cornices and other parts) directly use the hanging basket for manual mechanical grinding, the formwork interface seam staggered grinding, the degree of grinding should be smooth and does not expose the steel protective layer, the formwork interface staggered grinding to achieve a smooth transition. The surface after sanding is basically flat. When there are exposed rebar heads and embedded metal components on the concrete surface, the concrete around the exposed metal should be chiseled to fully expose the exposed metal, and then the exposed metal should be cut off or cut off along the lowest point to ensure that the remaining metal is less than 30mm below the concrete surface. For metal components with a large exposed area such as steel plates, the surrounding concrete should be chiseled first, the sharp edges and corners of the metal plate should be polished into an arc above R2mm, and then the sandpaper tray should be installed with a portable grinder to polish and remove rust to St3 on the exposed part of the embedded steel plate, and the corresponding metal anti-corrosion primer and intermediate paint should be painted according to the design requirements of metal anti-corrosion. The concrete chiseled surface is treated as required, the concrete of the chiseled part is repaired with polymer mortar, and the leveling is ensured. Finally, it is coated as a whole together with the concrete surface. (Note: (1) When cutting steel bars or grinding steel plates, the strength of concrete around the steel bars and embedded steel plates shall not be damaged.) (2) Under the premise of ensuring the thickness of the concrete protective layer, the smaller the scope of concrete chiseled, the better. (3) Pay attention to the matching of metal coating and concrete coating).

2.2.2 Remove dirt and oil to ensure that the wall surface is clean and dry.

2.2.3 Dust removal treatment: the dust and debris left on the surface after grinding are treated.

2.2.4 Anti-alkali treatment of the wall to reduce the pH value of the wall to below 10, which plays an important role in protecting the durability of the coating.

2.2.5 The dryness of the wall, the moisture content within 20mm of the wall should be less than 15%, otherwise the overall heat treatment measures should be adopted.

2.2.6 Requirements for the natural environment during the construction period: the temperature must not be less than 5 °C, the humidity must be less than 75%, and construction is strictly prohibited in rainy and windy weather. (Including the 24-hour range before and after rain).

2.2.7 The base layer with thicker thickness is repaired by layered filling method after sanding and smoothing.

2.3 Painting method

The coating of this project is carried out by a combination of airless spraying, roller coating and brush coating, and the primer is roller coating. And the construction personnel must be trained and skilled personnel with practical experience.

“Hongshun Construction Engineering Co., Ltd.” is a large-scale comprehensive construction enterprise integrating civil engineering, anti-corrosion, thermal insulation and steel structure. Specializing in aerial work, including new construction, maintenance, anti-corrosion, landscaping painting, demolition and other construction projects of towering structures (chimneys, hyperbolic cooling towers, ash storage silos).