Products

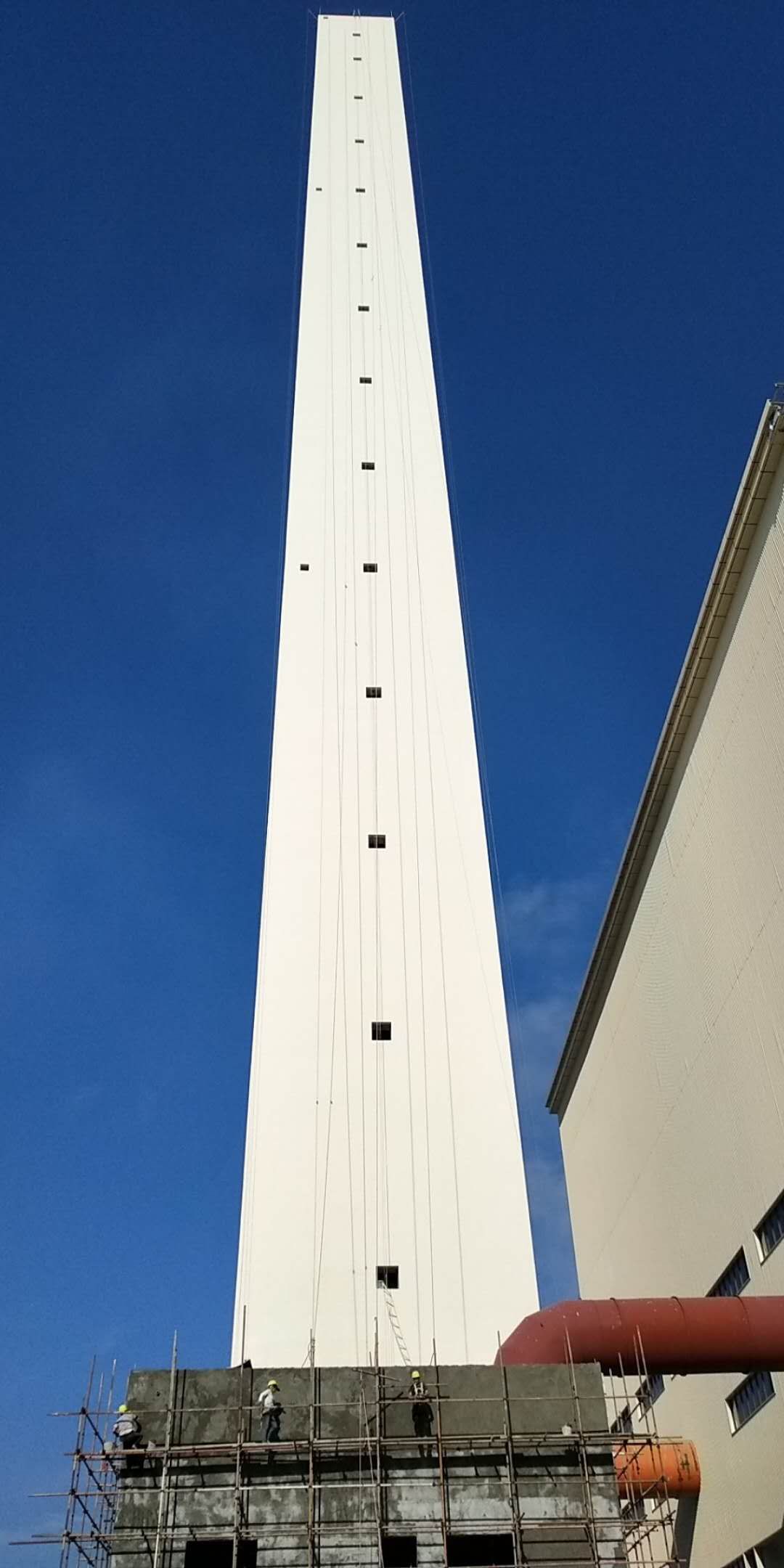

square chimney new

The main sub-construction scheme of the external structure of the cylinder

1. Operation platform system

1.1 The principle of hydraulic lifting mold turning process

Hydraulic formwork structure, formwork is installed in blocks, and the slope of the formwork is easy to adjust and control. Cumulative errors in construction can be avoided; After concrete pouring, because the concrete and the formwork do not run oppositely, the concrete will not cause damage when lifted on the climbing frame, and the quality of the concrete can be guaranteed; The formwork lifting is accurate in place, the tool-type support system is simple and convenient to operate, the labor intensity is low, and the ergonomics are high.

The principle of the chimney hydraulic lifting and turning construction device is to use the support rod buried in the reinforced concrete cylinder wall as the load-bearing body, and drive the operating platform system, vertical transportation system and formwork system through the hydraulic lifting system climbing.

1.2 Characteristics of hydraulic lifting mold turning process

The hydraulic lifting mold turning process is a new type of formwork system formed on the basis of absorbing the advantages of formwork system such as hydraulic sliding mold and large formwork without derrick, which has the characteristics of easy quality assurance, high safety and fast construction speed.

The hydraulic lifting and turning construction device is composed of operating platform system, vertical transportation system, formwork system, hydraulic lifting system, electrical control system and other parts.

“Hongshun Construction Engineering Co., Ltd.” is a large-scale comprehensive construction enterprise integrating civil engineering, anti-corrosion, thermal insulation and steel structure. Specializing in aerial work, including new construction, maintenance, anti-corrosion, landscaping painting, demolition and other construction projects of towering structures (chimneys, hyperbolic cooling towers, ash storage silos).